Description

|

Brand |

Iscar |

|

Cutting Direction |

Right Hand |

|

ECLASS Code |

21010901 |

|

Finish/Coating |

TiCN/TiN |

|

Inscribed Circle |

4.76 |

|

Insert Length |

8mm |

|

Insert Size |

8 |

|

Insert Type |

Laydown |

|

ISO Category Grade |

K M P |

|

ISO Cut |

K20 to K50 M30 to M40 P25 to P50 |

|

ISO Designation |

08IR 1.25 ISO |

|

Manufacturer Grade |

IC228 |

|

Material |

Carbide |

|

Material Application |

Stainless Steel Steel |

|

Number of Cutting Points |

3 |

|

Side to Cutting Tip |

0.7mm |

|

Teeth per Inch |

naTPI |

|

Thread Height Difference |

0.6mm |

|

Thread Pitch |

1.25 |

|

Thread Profile Type |

Full Profile |

|

Thread Standard |

ISO Metric |

|

Threading Location |

Internal |

|

UNSPSC Code |

23291804 |

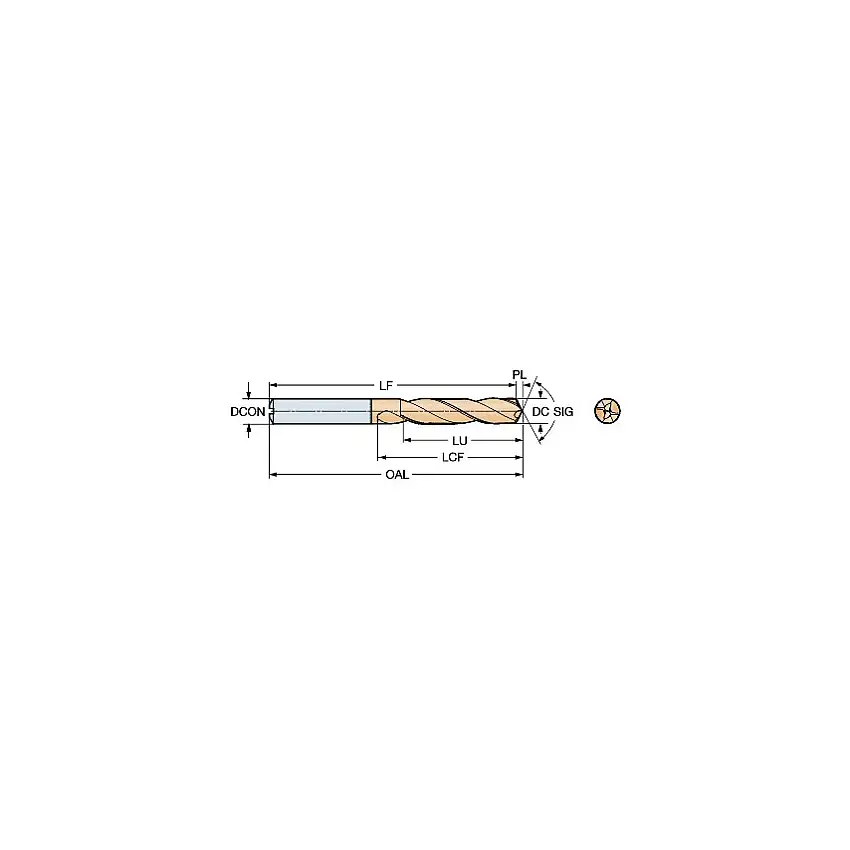

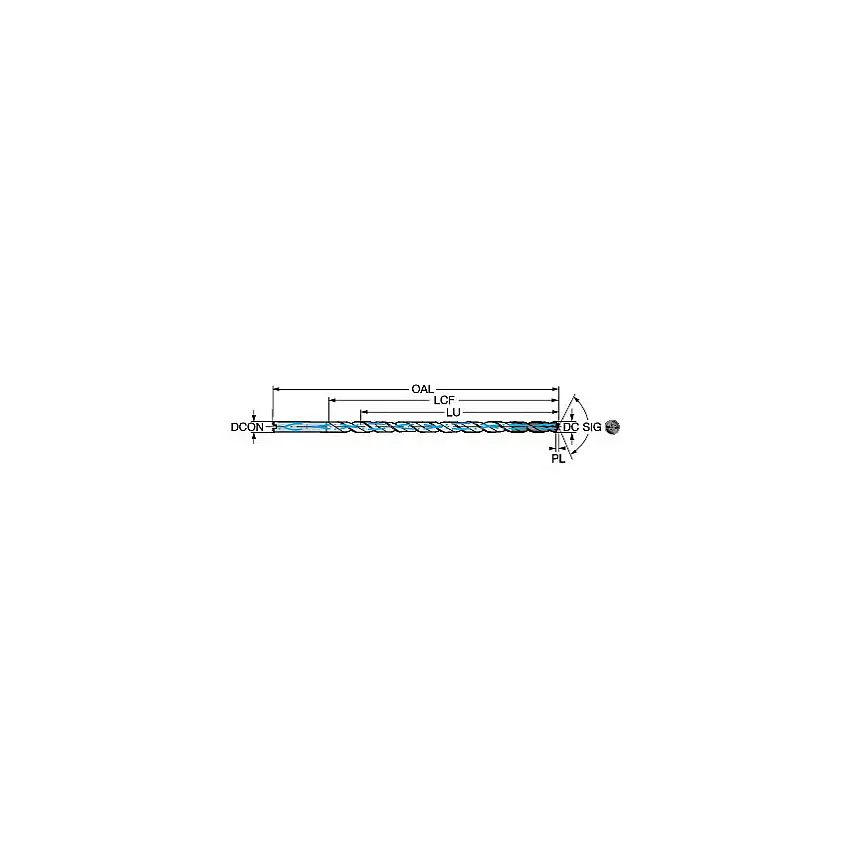

IR/L Metric Internal Threading Inserts

IR/L – ground periphery and rake

IRB -with a chipformer and peripherally ground

IRM – with a chipformer

Grade IC908

(P15-P30, M20-M30, K20-K30) PVD coated. Suitable for low to medium speed. IC908 high toughness for interrupted cuts. Excellent notch wear and build up edge resistance.

IC228 PVD COATED (P30-P50 K25-K40) For alloy steels, aluminum alloys, austenitic stainless steel, carbon steel, cast steel, copper alloys and Exotic alloys. Suitable for roughing andsemi-roughing in low speed / high feed and interrupted cut conditions. High resistance to mechanical & thermal shock.

Grade: IC250

For high loads and medium to high cutting speed.

ISO Range – P/M/K: (P15-P35)(M20-M40)

Grade or Coating Type: PVD

Coating Layers: TiCN+TiN

Reviews

There are no reviews yet.